|

|

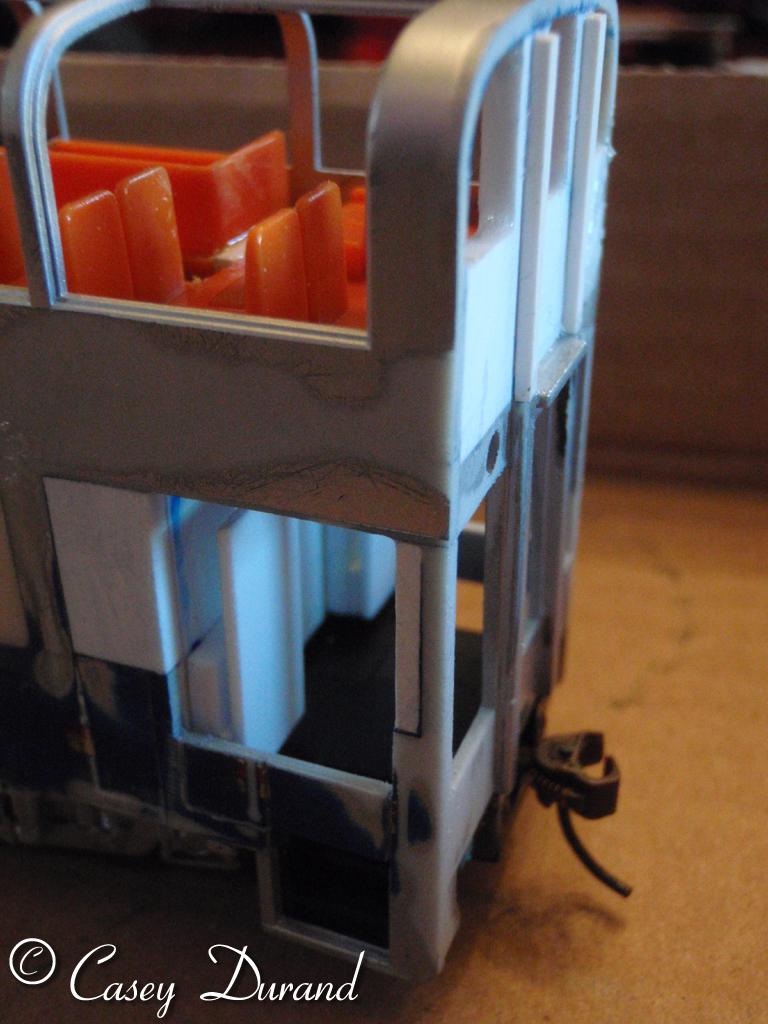

Royal Celebrity / Celebrity Cruises operates 4 Colorado Rail Car LLC. Ultra-Dome cars as part of their Alaska tour fleet. The model of these cars started as a Bachmann car prototyped after a Westours Corp. car. As the photos show some major chop-shop work was performed to accomplish the conversion. The first step was to rebuild the top level ends. The Westour cars are the only CRC domes built with angled windows, all others are square ended. Using a single window section for a spacer, pieces of roof from a doner can and some stock styrene, were used to rebuild a square end to the car. Custom windows then had to be cut and fitted into the new ends. Next was to move the lower side windows. This was accomplished by sectioning a strip of windows out of the doner car, fitting them into place, and filling the remaining void and windows. This may seem like a daunting task at first, especially when cutting into a car that costs almost $50. But the fact that these are completely smooth sided cars makes filling and sanding an easy task. One trick that I have developed in doing this is to do the major work with a stack of utility knife blades. I buy them by the pack of 100 and use them without a holder, between my fingers. This provides many advantages... A fresh blade is close at hand anytime, it is possible to lay the blade edge flat across the shell at a shallow angle and scrape (almost chisel) the bulk of material away, and the increase of control due to the fact that with a handle attached you can place too much force on the edge leading to a slipping of the blade resulting in an undesired goof-up. Another trick that I have began to use is replacing filler putty with a thickened plastic adhesive. If you have an older bottle of Plastruct Plastic Weld you might notice it has thickened. If you don't have a "naturally" thickened bottle you can simply add styrene scraps or junk sprue material to a partial bottle. After letting it dissolve a while, you now have a plastic filler that you can brush into place, it acts as an almost self-leveling filler, and it works at the same rate as the parent material. The two biggest advantages to this though are the facts that there is no worry about the body flexing and the filler flaking off or cracking in temperature changes and when you go to paint there are no issues with dissimilar surfaces / materials. When the lower vestibule was re-modeled, chair lifts built and final details added the car was coated with Model Master primer from a spray can. This thick coat further helped to smooth and fill small problem spots in the finish. A complete sanding job was then performed once more with a 2000 grit foam sanding block. Paint was applied again by spray can, Model Master gloss white enamel. Next was to install the windows, securing them with Micro Crystal Clear adhesive. The finial step was to apply the one-piece artwork. The "sticker" is a digital print from the original artwork, reduced to 1/86 of the "real" size. I opted for 1/86 instead of 1/87 scale to allow some wiggle-room on the model. With the addition of this car to the Durand fleet a modern consist of 12 cars can be made. The ARRC Goldstar service UltraDome is now in primer, after completion of that and a build of one each of the 5 unique Princess tour cars, a vintage 2008 consist of 18 cars can be run. Now remember 18 cars, P-30 and 2 SD-70 MAc will create a train over 20 feet long! Casey Durand |